AKPEROX Catalyst K is the suitable initiator for polymerization of Ethylene during Autoclave and pipe type processes, under high pressure. CATALYST K is used in the polymerization of both Ethylene and Vinyl Chloride. During polymerization of Ethylene, obtained a large spectrum in polymerization temperature and should be used in combination with other peroxides. During polymerization, it is used at temperatures between 50 - 70 °C as initiator for Suspension Vinyl Chloride Polymerization.

| Chemischer Name | |||

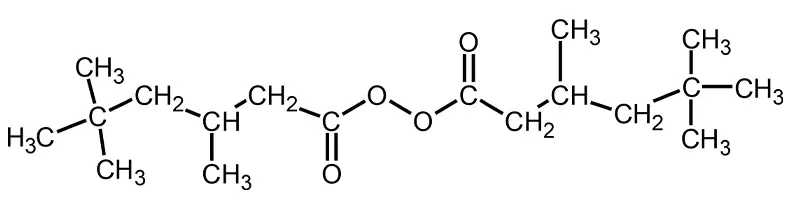

| Bis 3,5,5 -Trimethyl Hexanoyl Peroxide | |||

| CAS | UN | EINECS/ELINCS | ACRONYM |

| 3851-87-4 | 3115 | 223-356-0 | INP |

| AO(%) | ASSAY (%) | SADT (°C) | VISCOSITY |

| 3,76 - 3,88 | - | 20 | 13,0 mPa.s |

| DENSITY | METAL CONTENT | SOLID CONTENT | PEROXIDE CONTENT (%) |

| 0,875 ± 0,005 gr/cm3 | - | - | 74,0 - 76,0 |

| DILUENT | APPEARANCE | COLOR | STORAGE TEMPERATURE |

| Isododecane | Clear Liquid | Max. 30 APHA | -5˚C and -10˚ C. |

| PE PAIL | CARTON | BARREL | SHELF LIFE |

| 25 Kgs PE Drum | - | - | 3 Months |

| EIGENSCHAFTEN | |||

|

Must be kept between -5˚C and -10˚ C. Keep pails tightly closed. Store and handle in a dry, well-ventilated place, away from sources of heat, ignition and direct sunlight in original packaging. Provide grounding and venting in order to prevent static electricity build-up. Avoid any contact with Amine and Cobalt Accelerators, acids, alkalis and heavy metal compounds such as driers and metal soaps. |

|||

Als AKPA Kimya Ambalaj Sanayi ve Ticaret A.Ş. zeigen wir höchste Sensibilität für die Sicherheit Ihrer personenbezogenen Daten. In diesem Bewusstsein legen wir großen Wert auf die Verarbeitung und Speicherung aller Arten von personenbezogenen Daten aller Personen, die mit dem Unternehmen in Verbindung stehen, einschließlich derjenigen, die unsere Produkte und Dienstleistungen als Unternehmen in Anspruch nehmen, in Übereinstimmung mit dem Gesetz zum Schutz personenbezogener Daten Nr. 6698 ("BDS-Gesetz"). In voller Wahrnehmung dieser Verantwortung verarbeiten wir als für die Datenverarbeitung Verantwortlicher Ihre personenbezogenen Daten wie nachstehend erläutert und innerhalb der vom Gesetz vorgeschriebenen Grenzen.

Unser Grundprinzip ist die Wahrung Ihrer Privatsphäre und der Schutz der Grundrechte und -freiheiten bei der Verwendung Ihrer personenbezogenen Daten in unseren Diensten.

Zwecke und rechtliche Gründe für die Verarbeitung Ihrer personenbezogenen Daten:

Ihre Identitätsinformationen, Adresse, Telefonnummer, Steuernummer und andere Informationen, die im Rahmen von BDSG als personenbezogene Daten gelten, zu erfassen, um sie bei den Ihnen zu erbringenden Dienstleistungen im Rahmen der Gesetze und der einschlägigen Gesetzgebung, an die unser Unternehmen angeschlossen ist, zu verwenden, um unsere Dienstleistungen zu erbringen, um den Eigentümer und den Adressaten aller Arten von Geschäften und Transaktionen in diesem Rahmen zu bestimmen, um die Informationen und Dokumente zu organisieren, die die Grundlage für die auf Papier oder elektronisch durchzuführenden Arbeiten und Transaktionen bilden, um den gegenüber allen Justiz- und Verwaltungsbehörden gemäß den einschlägigen Gesetzen vorgeschriebenen Aufbewahrungs-, Melde- und Informationspflichten nachzukommen, um unsere Dienstleistungen im Rahmen der Gesetze, an die wir angeschlossen sind, zu erfüllen, um andere von unserer Gesellschaft angebotene oder angeforderte Dienstleistungen zu erbringen.

Bei Vorliegen einer der folgenden Bedingungen in Absatz 2 des Artikels 5 des BDSG mit dem Titel "Bedingungen für die Verarbeitung personenbezogener Daten" ist es möglich, personenbezogene Daten zu verarbeiten, ohne die ausdrückliche Zustimmung der betroffenen Person einzuholen:

1. Sie ausdrücklich gesetzlich vorgeschrieben ist.

2. Sie zum Schutz des Lebens oder der körperlichen Unversehrtheit der Person erforderlich ist, die ihre Einwilligung aufgrund tatsächlicher Unmöglichkeit nicht erteilen kann oder deren Einwilligung nicht rechtsgültig ist.

3. Es ist notwendig, personenbezogene Daten der Vertragsparteien zu verarbeiten, sofern dies in unmittelbarem Zusammenhang mit der Begründung oder Erfüllung eines Vertrags steht.

4. Sie für den für die Verarbeitung Verantwortlichen zwingend erforderlich ist, um seine rechtlichen Verpflichtungen zu erfüllen.

5. Sie von der betroffenen Person selbst bekannt gemacht wurde.

6. Die Datenverarbeitung ist für die Begründung, die Ausübung oder den Schutz eines Rechts zwingend erforderlich.

7. Die Datenverarbeitung ist zur Wahrung der berechtigten Interessen des für die Verarbeitung Verantwortlichen erforderlich, sofern die Grundrechte und Grundfreiheiten der betroffenen Person dadurch nicht beeinträchtigt werden.

Übermittlung Ihrer persönlichen Daten:

Auch ohne die ausdrückliche Zustimmung des Inhabers der personenbezogenen Daten können personenbezogene Daten an Dritte weitergegeben werden, indem alle erforderlichen Sicherheitsmaßnahmen, einschließlich der vom Vorstand festgelegten Methoden, mit der gebotenen Sorgfalt von unserem Unternehmen ergriffen werden, wenn eine oder mehrere der folgenden Bedingungen erfüllt sind.

1. Die einschlägigen Tätigkeiten im Zusammenhang mit der Übermittlung personenbezogener Daten sind in den Gesetzen eindeutig festgelegt,

2. Die Übermittlung personenbezogener Daten durch das Unternehmen ist mit dem Abschluss oder der Erfüllung eines Vertrags verbunden unmittelbar verbunden und notwendig,

3. Die Übermittlung personenbezogener Daten zur Erfüllung einer rechtlichen Verpflichtung unseres Unternehmens zwingend erforderlich ist,

4. Sofern die personenbezogenen Daten von der betroffenen Person öffentlich gemacht wurden, die Bekanntgabe von unserer Gesellschaft in begrenztem Umfang zu ihrem Zweck übermittelt werden,

5. Die Übermittlung personenbezogener Daten durch unser Unternehmen für die Begründung, Nutzung oder den Schutz der Rechte des Unternehmens oder der betroffenen Person oder Dritter zwingend erforderlich ist,

6. Die Übermittlung personenbezogener Daten ist für die berechtigten Interessen des Unternehmens zwingend erforderlich, sofern dadurch die Grundrechte und Grundfreiheiten der betroffenen Person nicht beeinträchtigt werden,

7. Das Leben oder den Körper der Person, die ihre Einwilligung aufgrund tatsächlicher Unmöglichkeit nicht erteilen kann oder deren Einwilligung nicht als rechtsgültig anerkannt ist sie für den Schutz ihrer Integrität zwingend erforderlich ist.

Darüber hinaus können personenbezogene Daten bei Vorliegen einer der oben genannten Bedingungen in Länder übermittelt werden, die vom Verwaltungsrat als Länder mit angemessenem Schutz ("Foreign Country with Adequate Protection") bezeichnet werden. Wenn kein angemessener Schutz besteht, können personenbezogene Daten gemäß den in der Gesetzgebung festgelegten Bedingungen für die Datenübermittlung ins Ausland übermittelt werden, wenn sich die für die Datenverarbeitung Verantwortlichen in der Türkei und im jeweiligen Ausland schriftlich zu einem angemessenen Schutz verpflichten und der Vorstand seine Zustimmung erteilt hat ("Ausland, in dem der für die Datenverarbeitung Verantwortliche sich zu einem angemessenen Schutz verpflichtet").

Löschung, Vernichtung oder Anonymisierung von personenbezogenen Daten;

a. Personenbezogene Daten werden, auch wenn sie gemäß den Bestimmungen dieses Gesetzes und anderer einschlägiger Gesetze verarbeitet wurden, von dem für die Verarbeitung Verantwortlichen von Amts wegen oder auf Antrag der betroffenen Person gelöscht, vernichtet oder anonymisiert, wenn die Gründe für ihre Verarbeitung entfallen.

b. Vorbehalten bleiben die Bestimmungen anderer Gesetze über die Löschung, Vernichtung oder Anonymisierung von Personendaten.

c. Die Verfahren und Grundsätze für die Löschung, Vernichtung oder Anonymisierung von Personendaten werden durch Verordnung geregelt.

Ihre Rechte nach Artikel 11 des Gesetzes:

Das Indem Sie sich an unser Unternehmen wenden, Ihre persönlichen Daten;

1. Zu erfahren, ob Ihre persönlichen Daten verarbeitet werden oder nicht,

2. Im Falle der Verarbeitung Informationen anzufordern,

3. Den Zweck der Verarbeitung zu erfahren und ob sie in Übereinstimmung mit ihrem Zweck verwendet werden,

4. Die Dritten zu kennen, an die sie im In- und Ausland weitergegeben werden,

5. Die Berichtigung unvollständiger/falsch verarbeiteter Daten zu verlangen,

6. Die Löschung/Vernichtung personenbezogener Daten im Rahmen der im Artikel über die Löschung, Vernichtung oder Anonymisierung personenbezogener Daten von BDSG festgelegten Bedingungen zu verlangen,

7. Zu verlangen, dass die gemäß den Absätzen (5) und (6) vorgenommenen Transaktionen den Dritten, an die sie übermittelt werden, mitgeteilt werden,

8. Sich dagegen zu wehren, dass ein Ergebnis zu Ihrem Nachteil entsteht, das ausschließlich auf die Analyse durch automatisierte Systeme zurückzuführen ist,

9. Sie haben das Recht, Schadenersatz zu verlangen, wenn Ihnen durch eine unrechtmäßige Verarbeitung ein Schaden entstanden ist.

Der für die Datenverarbeitung Verantwortliche, an den Sie sich im Rahmen des Gesetzes wenden können:

KONTAKTANGABEN

AKPA Kimya Ambalaj Sanayi ve Ticaret A.Ş.

Kontakt-Link: www.akpakimya.com

Yenibosna Zentrum Nachbarschaft Ladin Strasse No:36/70 Townofis Floor:12 34197

Bahcelievler, Istanbul, Türkei

Telefon: +90(212)580 55 59

E-Mail: info@akpakimya.com

Lütfen, belgeyi indirmek için formu doldurun

En kısa sürede belge mail olarak tarafınıza iletilecektir

Suche